Barelle Limited started out in January 2005 with the view to build a successful Sub-Contract Sheetmetal & fabrication company supplying high quality, cost effective products with an efficient, hardworking and friendly service. The mission was to take the worry & stress form our customers by dedicating ourselves to them with a 100% focused and dependably service.

Over the years these core values have allowed us to gain not only additional knowledge & experience but also allow us to target additional work in other areas of the industry. Through our reliability and dedication, we have successfully secured further customers across various sectors resulting in bigger projects with larger orders. As a result, we are now manufacturing products in sectors such as Data Centres, Swithgear, Point of sale, Machine frames, Lighting, & Furniture.

As we move froward and grow, our customers continue to be satisfied with our full commitment to them, resulting in a professional and friendly working relationship which we believe will bring us further success and growth in the future.

2005 – Company starts manufacturing with Manual Boschert Punch, Pressbrake, Box and Pan folder, Guillotine ,Bandsaw ,Pillar drill and powder coating booth & oven.

2006 – Spray Booth 6mtr X 3mtr was bought so we could spray longer parts for a customer.

2008 – Machinery upgrade with first CNC Press brake (second-hand) & extra employees to allow us to keep up with growth into new sectors.

2012 – With increased orders and new customers we outgrew our current premises so bought a larger unit in Weatherwell Business Park, Clondalkin, Dublin22

2013 – Purchased a new Powder Coating Spray booth and our first automatic punch machine a Trumpf Trupunch 1000

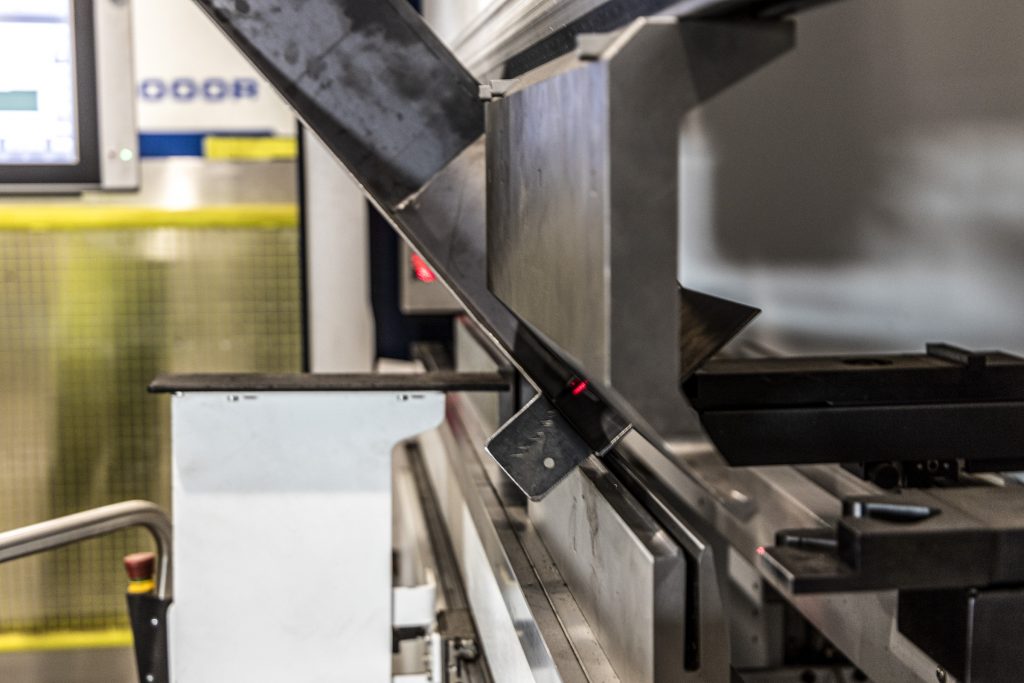

2016– Purchased a New CNC pressbrake to keep up with orders and also bought a 3ton Flatbed truck for collection & deliveries

2017 – Secured a contract which meant moved our powder coating into another unit and bought additional Spray Booth & Batch oven to increase capacity also bought a LVD Turrent Punch allowing us to speed up production.

2019 – We added a second automatic punch a Trumpf 3000 punch & third CNC pressbrake allowing us to increase production capacity and shorten leadtimes.

2020 – Purchased are Fourth CNC pressbrake a Trumpf Trubend 3100 and added 2no Kemppi 253R 250 amp welders

2021– Due to additional growth with one of our customers we purchased a Hydraulic tapping arm allowing us to Tap up to M16 in size and reduce labour time.